The Future of Heating Equipment is Electric: Heat Pump Technology Deep Dive

HOW A BUILDING AUTOMATION SOLUTION CONTRIBUTES TO DECARBONIZATION

According to research conducted by the scientific teams of Project Drawdown, building automation systems (BAS) can boost heating and cooling efficiency by more than 20% and reduce energy use for lighting, appliances, etc., by 8%. Globally, BAS adoption ranges from 0% to 75% in high income countries. Substantially expanding adoption—at a net first cost of US $287.70-393.35 billion—could save building owners $2.27-3.42 trillion (US) in operating costs. It could also avoid 9.55-14.01 gigatons of CO2 emissions by 2050.1

1. Project Drawdown, Building Automation Systems. Web.

TYPES OF COMMERCIAL HEAT PUMPS

Traditionally, heat pumps were seen as a residential heating and cooling solution, and rarely scaled to the sizes needed for larger buildings. Their use was limited to climates with outdoor temperatures greater than, say, 20°F. Below that temperature, second stage heat from either fossil fuel or electric resistance is activated. Even in temperate climates, heat pumps must periodically defrost. The same constraints that limit heat pumps in residential use in colder climates require the same considerations for commercial buildings—on a much bigger scale.

Despite their limitations, heat pumps are increasingly available for commercial applications, from small to large buildings as their use is expanding to cold climates. Different all-electric equipment types like VRF, packaged units, split systems and chillers may be considered heat pumps. Because they do not generate heat and simply move heat, they can be up to three times more efficient than other forms of electrified heating.

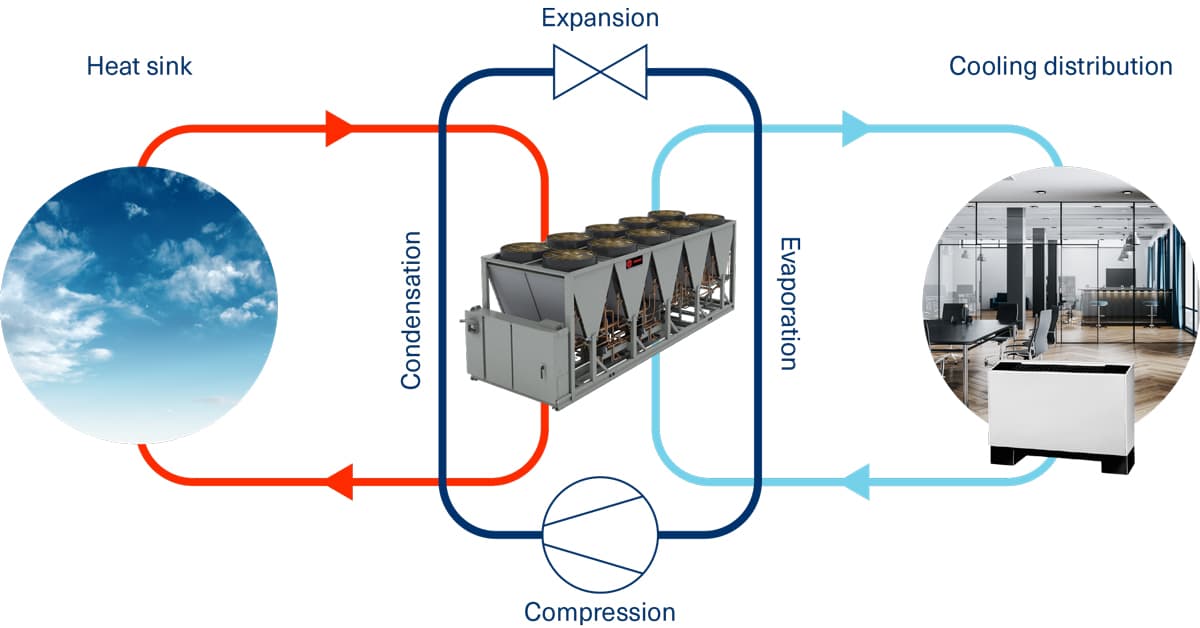

During warmer days, heat pumps extract heat from the building and releases it to the atmosphere, just like an air-cooled chiller.

HEAT PUMPS CONSIDERATIONS

There are many factors to consider when selecting the best electrified heating system for an application. A location’s climate zone is a good starting point, as heat pump performance is highly dependent on ambient conditions. As ambient temperature drops, heat pump COP decreases—especially for air-source heat pumps. Ambient temperature and humidity also affect the need for defrost. The defrost cycle reverses the refrigeration cycle, applying heat to the outdoor coil to melt frost when condensate freezing is detected. For single circuit heat pumps, defrost mode consumes all the unit’s heat, leaving none for space heating and resulting in cold air being sent into the occupied space. Dual fuel (natural gas) and auxiliary (electric resistance) backup can be used in some heat pumps to compensate for this limitation. Systems may employ advancements in thermal energy storage systems, higher leaving hot water temperatures for heat recovery and cascade systems to optimize heating sources.

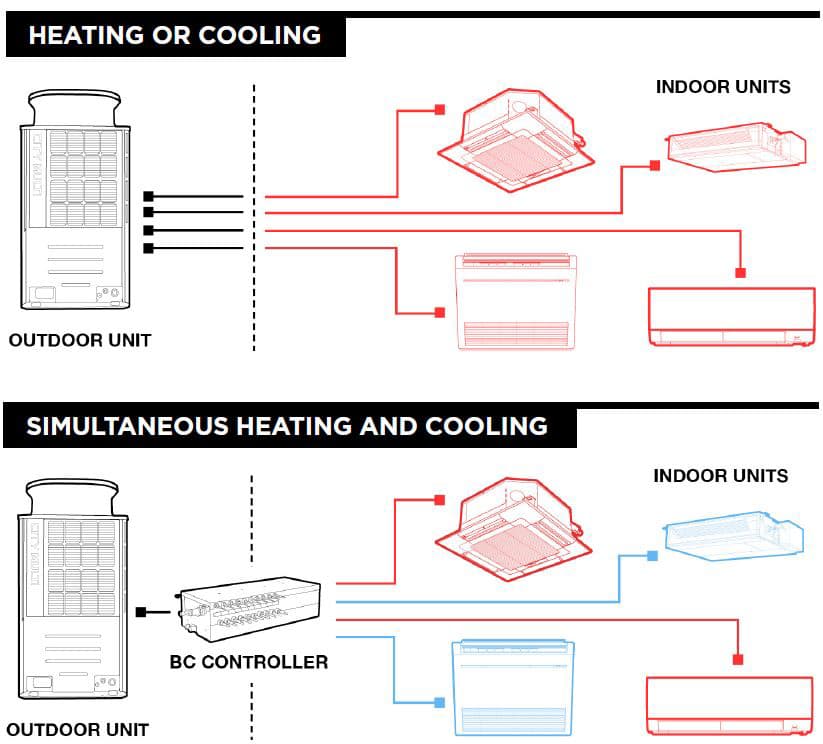

Variable Refrigerant Flow (VRF) Systems

A VRF system consists of an outdoor unit and up to 50 indoor units connected via refrigerant lines and a communications network. Each zone is conditioned by its own indoor unit(s) and can have its own set point. Instead of burning fossil fuels, VRF heat pumps use compressor vapor injection to extract ambient heat from outdoor air or a water source and bring it inside the building. During cooling, VRF heat pumps reverse this process, transferring heat from zones to the outdoor unit which then rejects it. Typically, VRF runs in tandem with a dedicated outdoor air system (DOAS) that controls ventilation and regulates humidity. Indoor units are available in ductless and ducted styles. VRF is commonly used in small- to medium-sized buildings but may also be applied to larger buildings.

TRANE SOLUTION

Trane® / Mitsubishi Electric VRF Systems consolidate heating and cooling into one all-electric, multi-zone system. With several options for outdoor units, branch controllers and indoor units including hybrid water and refrigerant cooling, the Trane / Mitsubishi Electric VRF portfolio can be configured for a variety of buildings, new and existing, including offices, hotels, schools, multi-family, and mixed-use spaces. Seamlessly integrate any configuration into Tracer® SC+ and Trane Controls including Air-Fi® Wireless for total system optimization.

Understanding VRF System Types

Heat Pump VRF technology consolidates heating and cooling into one all-electric, multi-zone system for a range of commercial applications. This type of VRF system consists of an outdoor unit and up to 50 indoor units connected via refrigerant lines and a communications network. Each zone is conditioned by its own indoor unit(s) which can have unique set points. Instead of burning fossil fuels, VRF heat pumps provide heating to zones by introducing ambient heat that the outdoor unit extracts from the air or a nearby water source.

Heat Recovery VRF systems have the same capabilities as VRF heat pumps, but they also use a branch circuit (BC) controller to leverage load diversity and provide simultaneous heating and cooling. They can move heat from zones that require cooling to zones that require heating. By repurposing thermal energy that would have been rejected by the outdoor unit, heat recovery systems increase total applied capacity and energy efficiency.

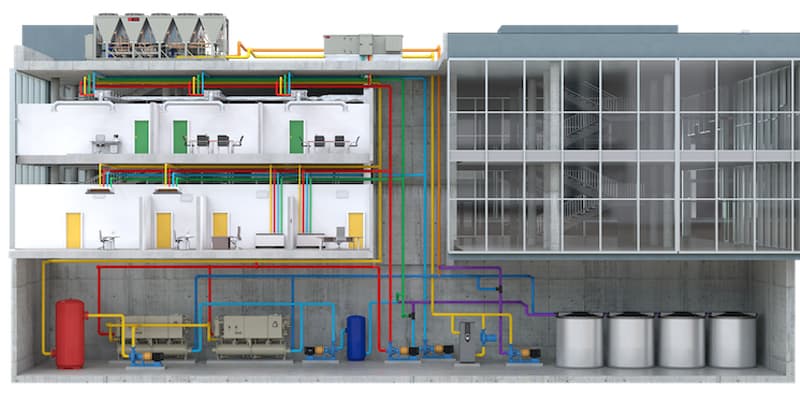

Hydronic Systems

“Hydronic” refers to an HVAC system that uses water to transfer energy to heat or cool. Depending on the application, a hydronic system can extract heat from an air or water source and deliver hot water for heating (such as in-floor heating) and for general uses. Hydronic systems are suitable for small to large commercial buildings, can include several different technologies including packaged unit and split systems as well as chillers configured to both cool and heat, boilers and/or auxiliary heat pumps.

TRANE SOLUTION

A comprehensive chiller-heater solution from Trane provides guidance on how to apply heat pumps for reliable, cost-effective, energy-efficient options to cool and heat facilities while reducing carbon emissions. It also supports indoor air quality (IAQ) objectives because it can be applied to fit with many central air-handling and dedicated outdoor air systems, as well as zone terminal products such as fan coils, unit ventilators, sensible cooling units and VAV terminals.

Trane Comprehensive Chiller-Heater Systems deliver what building owners need:

Flexibility—to satisfy diverse heating and cooling loads and comply with electrification regulations and sustainability objectives.

High performance—by exploiting significant improvements in heat pump heating to enable buildings to function better and reduce carbon emissions.

Reliability—by managing equipment capabilities to reduce the impact of defrost on system performance and enabling cold climate operation.

Lower cost of ownership—by reducing equipment and energy costs while increasing efficiency and reliability for building owners.

Packaged Units and Split Systems

For small to mid-size applications, there are several types of heat pumps designed specifically for ease of retrofit including packaged terminal heat pumps, split system heat pumps, rooftop unit (RTU) heat pumps and water source heat pumps. All these products share similar footprint and accessibility to their respective gas heat counterparts, allowing for an in-kind replacement. However, they are limited on cold climate capability to varying extents and may require dual fuel or auxiliary backup for some applications.

Consisting of an outdoor unit and air handler, packaged units are the most common type of heat pump used in commercial buildings. For heating, a packaged system pumps outside heat into the building using a compressor and vapor compression cycle. Conversely, it cools a building by pumping heat out of it through a reversible refrigeration cycle.

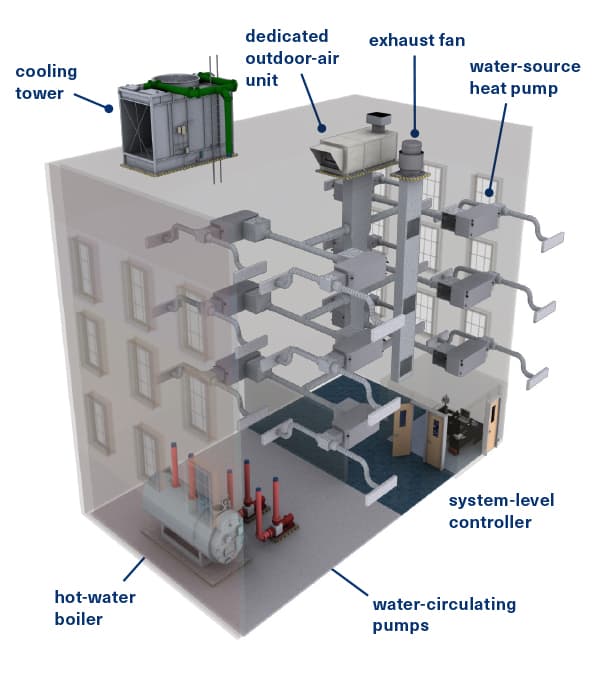

A water source heat pump (WSHP) transfers the heat via heat exchanger into pipes that carry water through the building. Typically, the loop temperature is maintained within limits to enable efficient heating and cooling with a central cooling tower and boiler. By connecting all units to this common loop, heat recovery between spaces is enabled. With multiple configurations and the ability to place WSHP units in dropped ceilings or hidden in mechanical rooms, they offer design flexibility for buildings with a lot of occupied spaces such as multi-family housing.

A water source heat pump (WSHP) typically heats or cools a particular zone in a building. A WSHP contains all the components of a refrigeration circuit, including one or more compressors, a refrigerant-to-air heat exchanger, a refrigerant-to-water heat exchanger and an expansion device. In addition, a reversing valve allows the WSHP to reverse the direction of refrigerant flow and change the operation of the refrigeration circuit to provide either cooling or heating.

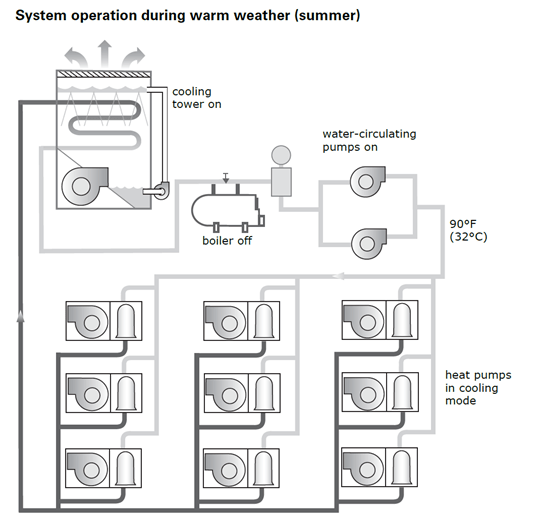

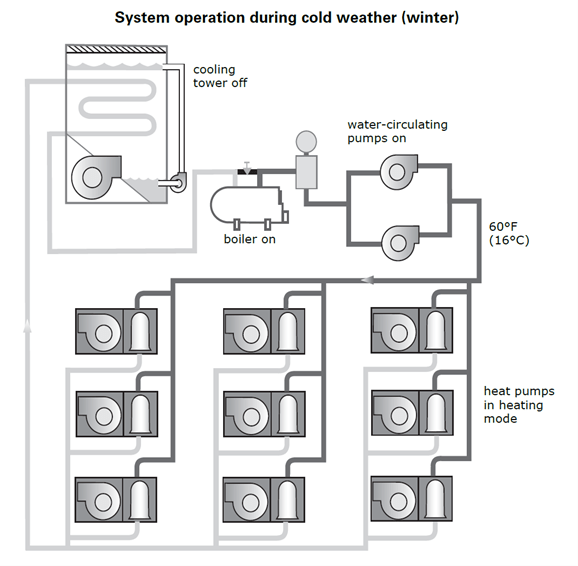

During mild weather, such as spring or fall, the heat pumps serving the sunny perimeter and interior of the building may operate in cooling mode and reject heat to the water loop. At the same time, the heat pumps serving the shady perimeter of the building may operate in heating mode and extract heat from the water loop. Heat rejected by units operating in cooling mode raises the loop temperature while heat extracted by units operating in heating mode lowers the loop temperature. If the water temperature stays between about 60ºF (16ºC) and 90ºF (32ºC), for example, neither the boiler nor the cooling tower needs to operate. In this manner, a WSHP system provides a form of heat recovery.

TRANE SOLUTION

Trane’s packaged units and split systems portfolio includes a full line of air conditioners and heat pumps for small commercial applications. Matching air handlers are available with single- or variable-speed motors for year-round, energy efficient comfort.

During cold weather, when most (or all) of the heat pumps are operating in heating mode, heat is extracted from the water loop and transferred to the air. This causes the temperature of the water in the loop to decrease, making it necessary to add heat to the water. A “heat adder” (such as a hot-water boiler) is used to add heat to the loop, maintaining a leaving water temperature of approximately 60ºF (16ºC).

A split system affords similar design flexibility for buildings of any size when rooftop access is not ideal. Simple and inexpensive, split systems may be used in residential houses or small office and professional buildings. They are not recommended for extremely cold climates, however, as it’s more difficult to extract heat from air at frigid temperatures. For heating in cold climates, these heat pumps are typically paired with a gas-burning furnace.

One of the most common types of dedicated outdoor air (OA) equipment is a standalone, air-cooled, direct-expansion (DX) unit. This might be a packaged unit or a split system (comprised of two separate sections connected by refrigerant piping). A packaged DX unit is typically installed on the roof of the building and contains a fan, filter, a gas-fired burner, or heating coil and all the components of a DX refrigeration system—an evaporator (cooling) coil, one or more compressors, an air-cooled condenser complete with propeller-type fans and expansion devices. In addition, it may contain an air-to-air heat exchanger for exhaust-air energy recovery.

A split DX system is comprised of a condensing unit—which contains one or more compressors and an air-cooled condenser with propeller-type fans— and an air-handling unit (AHU)—which contains the evaporator coil and expansion devices, along with a fan, filter, heating coil or gas-fired burner and possibly an air-to-air heat exchanger. The condensing unit is typically installed on the roof or on the ground next to the building, while the AHU can be installed indoors or outdoors. The two components are connected by field-installed refrigerant piping to complete the refrigeration circuit. A packaged unit typically offers less flexibility in selection and fewer options, while a split DX system increases flexibility since the AHU typically has more options for fans, air cleaning devices, air-to-air energy recovery devices and sound attenuation.

The primary advantages of using air-cooled DX equipment as the dedicated OA unit are lower installed cost (typically) and simplicity in design and installation, especially when a packaged unit is used. The selection and performance of the standalone unit is independent of the WSHPs and other components of the water distribution loop.

Additionally, the dedicated OA unit can be operated (to control indoor humidity after hours, for example) without requiring the pumps, and possibly the boiler or cooling tower, to operate. The drawbacks of this approach include limited flexibility (especially when a packaged unit is used), lower efficiency and installation of some or all of the equipment outside.

Chillers

Chillers today can do more than cool spaces. Many models can be configured with heat pumps and heat recovery to provide simultaneous cooling and heating.

Chillers Configured with Heat Recovery and as Heaters

Adding heat recovery to a chiller is a common first step toward electrification of heat. Heat recovery chillers use existing heat that would otherwise be wasted in the cooling process. To be beneficial, they require a simultaneous demand for cooling and heating, but they are one of the most efficient forms of heating available.

Heat recovery units are set to the cool water set point. So, as long as there is a demand for cooling, the unit can also provide heat.

When a building is heating-dominant, water-cooled chillers may be controlled to the hot water set point to operate primarily as heaters instead. These systems are extremely energy efficient and easy to implement. (Note that water-cooled chillers may also be referred to as heat pumps since they can move energy to heat the spaces within the building.)

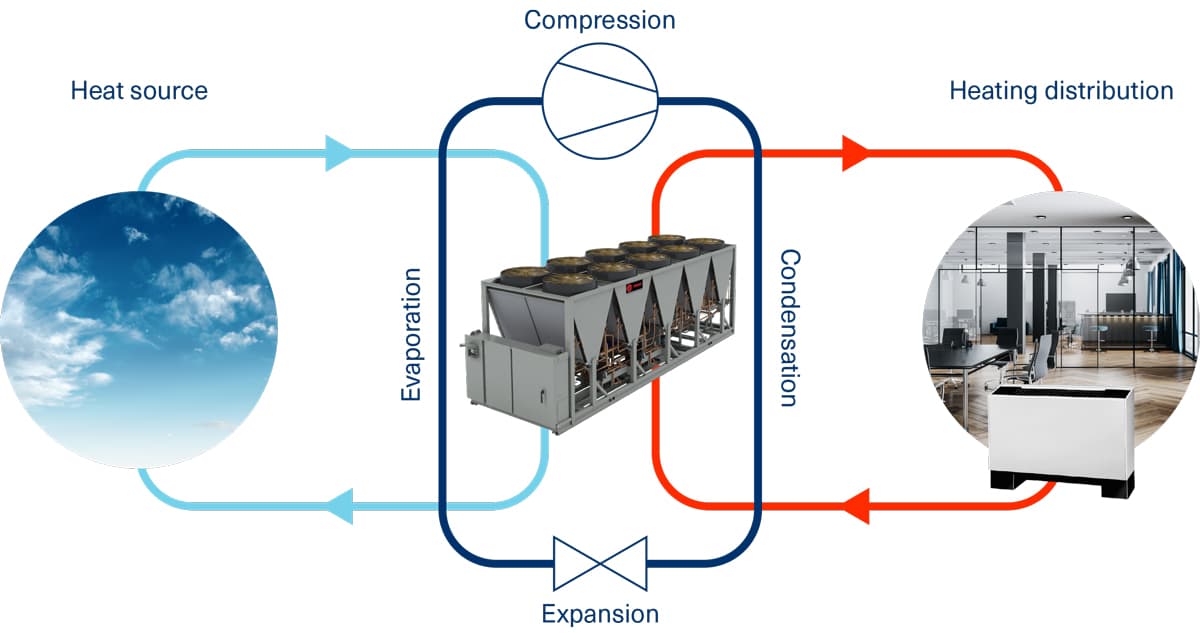

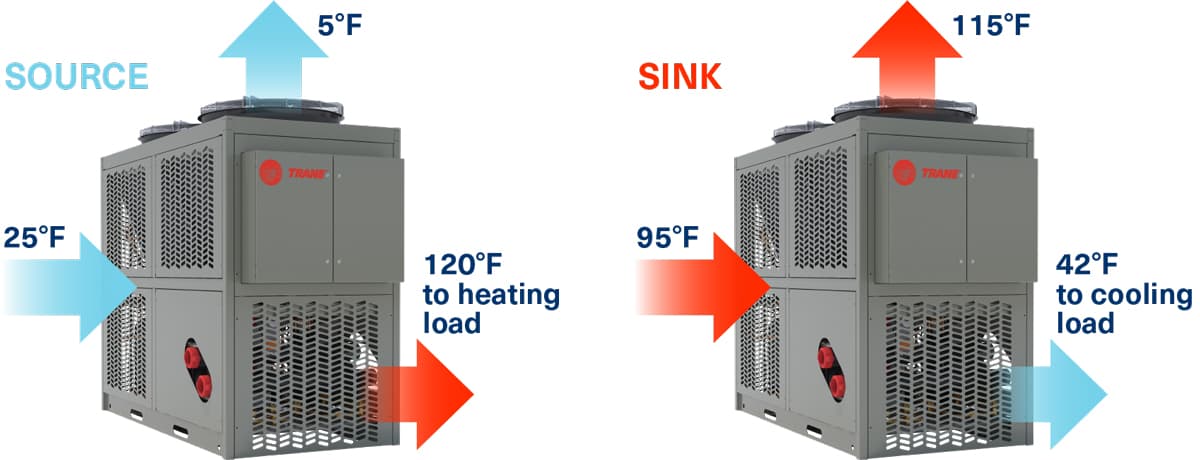

Reversible Heat Pumps and Multipipe Units

A key enabler for decarbonization, a chiller configured with a reversing valve can move energy in two directions to provide electrified heating or cooling. Electrifying your building and heating with either an air-source or water-source heat pump not only helps meet your decarbonization goals but can also be far more efficient than using a natural gas boiler.

Heat Pump

- A heat pump with a reversing valve is a unit which allows the evaporator and condenser to switch roles by reversing the flow of refrigerant within the circuit.

- Heat pumps can come in a wide range of sizes and are available in water-source and air-source versions

Multipipe units can provide simultaneous cooling and heating because they can be controlled to both the heating and cooling set points. More energy-efficient than other forms of electric heating, they’re also the most flexible, because one unit can provide heating, cooling or both, regardless of the dominant load. However, multipipe units are likely to have a higher initial cost than other chiller heating technologies.

TRANE SOLUTION

Trane air-to-water heat pumps provide heating or cooling from one all-electric source to support compliance with policies and incentives to decarbonize buildings. The air-to-water heat pumps are available in either modular or packaged units.

Trane’s packaged unit, the Ascend® Air-to-Water Heat Pump model ACX comes in six sizes ranging from 140 to 230 tons of nominal cooling and 1500 to 2500 MBh heating capacity and complies with ANSI/ASHRAE/IES 90.1-2019. It provides an energy-code-compliant electrification solution that can serve the needs of a broad spectrum of commercial buildings, including government facilities, commercial real estate, K-12 schools, hospitality and out-patient healthcare facilities.

Trane’s modular unit, the Theramfit™ Air-to-Water Heat Pump model AXM is easy to install (and expand) especially in dense urban environments and retrofits. AXM modular heat pumps move through freight elevators and fit on urban rooftops. Each modules nominal capacity is 30 tons of cooling and 390 MBh in heating. Connect up to 10 heat pumps for a nominal 300-ton bank. AXM uses vapor injection compressors to extend the effective operating range of the scroll compressor which provides reliable comfort in colder climates. This feature allows for higher leaving hot water temperatures down to 0 degrees Fahrenheit outdoor ambient temperature.

Storage-Source Heat Pump Systems

Thermal energy storage has been and will continue to be a key tool to decarbonize. Because thermal energy storage can capture and store thermal energy for heating and cooling, thermal energy storage provides ultimate flexibility to reduce summer and winter peak electricity demand, optimize carbon reduction and lower operating cost.

A storage source heat pump (SSHP) system combines the functionality of a heat pump with storage tanks for thermal energy, typically ice tanks. Essentially, an energy recovery technology is typically used in cold climates where air source heat pumps lose capacity and require a different source of energy. Excess heat is stored in the tanks. A heat pump moves the energy from the tanks to either reject it to the atmosphere in the summer or into the building to heat it in the winter. Unlike an air source heat pump, the source energy in a SSHP is never below 32°F (0°C) which results in much higher COPs.

TRANE SOLUTION

Trane offers a portfolio of complete thermal energy storage systems for cooling and heating built on Trane’s expertise in chillers, thermal energy storage tanks, controls, and service. Liken thermal energy storage to a battery for your HVAC system. It gives you the ability to store and dispatch thermal energy, based on operational needs, utility rates/programs, and availability of renewable resources.

Commercial Hot Water Heaters

Domestic hot water (DHW) accounts for roughly 25% of annual energy usage in typical multifamily buildings2 and 25% in both passive house3 and new multifamily construction.4 This energy expenditure is costly for building owners and comes at a significant environmental impact in the form of greenhouse gas emissions that contribute to climate change.

DHW heat pump water heaters transfer ambient thermal energy from outdoor air to potable water by cycling refrigerant. Optimal performance and cost benefits for all-electric heat pumps require proper design, installation, and commissioning. This starts with cooperation and information exchange among project team members, including the developer or building owner who will decide whether the facility will participate in utility demand-response programs. Designers must understand the building’s demand profile, inclusive of the gallons per hour, duration and timing associated with peak loads and off-peak loads. The system’s storage capacity is based on how often the system will run. Additionally, designers account for climate and may make provisions for snow, rain, wind, and marine salt.

2. U.S. Energy Informational Administration

3. Passive House Institute US

4. Bonneville Power Administration

TRANE SOLUTION

HEAT2O™ is an all-electric CO2 refrigerant heat pump water heater designed to improve sustainability and reduce energy consumption in multifamily buildings and large-scale commercial facilities. Intended to heat water for human consumption rather than heating air, HEAT2O transfers ambient thermal energy from outdoor air to potable water by cycling refrigerant.

Natural CO2 refrigerant enables HEAT2O to supply hot water up to 176°F even in low ambient conditions without burning fossil fuels. The system achieves highly efficient heat exchange with three refrigerant lines wrapped around a twisted water pipe. The CO2 refrigerant flows in the opposite direction of the water. Running the refrigerant lines along the pipe’s grooves increases the heat conductive area while the spiral helps create a vortex in the pipe, accelerating the turbulence effect of water and reducing pressure loss in the heat exchanger. Additionally, the copper pipes make for double-walled construction. An inverter-driven scroll compressor increases HEAT2O’s energy efficiency by enabling the system to modulate refrigerant flow and heating capacity to match loads.

HEAT2O can provide over four times more energy as heat than the system consumes in electricity. With a coefficient of performance (COP) of up to 4.52, HEAT2O offers energy savings of up to 60% to 70% for building owners and tenants compared to electric-resistance water heaters.

Achieving Decarbonization Goals

Today’s heat pump technologies provide a variety of ways to help building owners comply with regulations around decarbonization and meet their ESG goals. While some building operations may allow for total electrification of heat in a single upgrade or new construction, others may require a phased or hybrid approach.

The flexibility of heat pump systems enables building owners to craft a solution based on their budget, needs and goals. Each building that achieves electrification of heat helps society as a whole take positive steps to address climate change challenges.