High performance building solution saves energy, boosts bottom line • Tuam, Ireland

With a clear focus on energy efficiency, environmental stewardship and the bottom line, Transitions Optical is working with Trane to enhance eyeglass lens production while saving energy and production costs. Thanks to advice from Trane and a Select Service Agreement, Transitions Optical has cut lens production costs by 50 percent while generating 144,000 ($192,000 USD) in annual energy savings. In recognition of Transitions Optical’s commitment to energy efficiency and environmental responsibility, the Transitions Optical plant in Tuam, Ireland, has been awarded the Trane "Energy Efficiency Leader Award"--the first business in Ireland to receive this honor.

Challenge

In late 2006 Transitions Optical engineers initiated a plan to address rising energy costs and aging infrastructure. A building audit was used to identify energy conservation measures and then develop a three-year plan to upgrade chilled water systems and controls with more efficient systems. Very importantly, Transitions Optical must avoid production stoppages. Key factors in reaching their goals included confidence in the stable production of chilled water for manufacturing operations, and the expertise of their supplier.

Solution

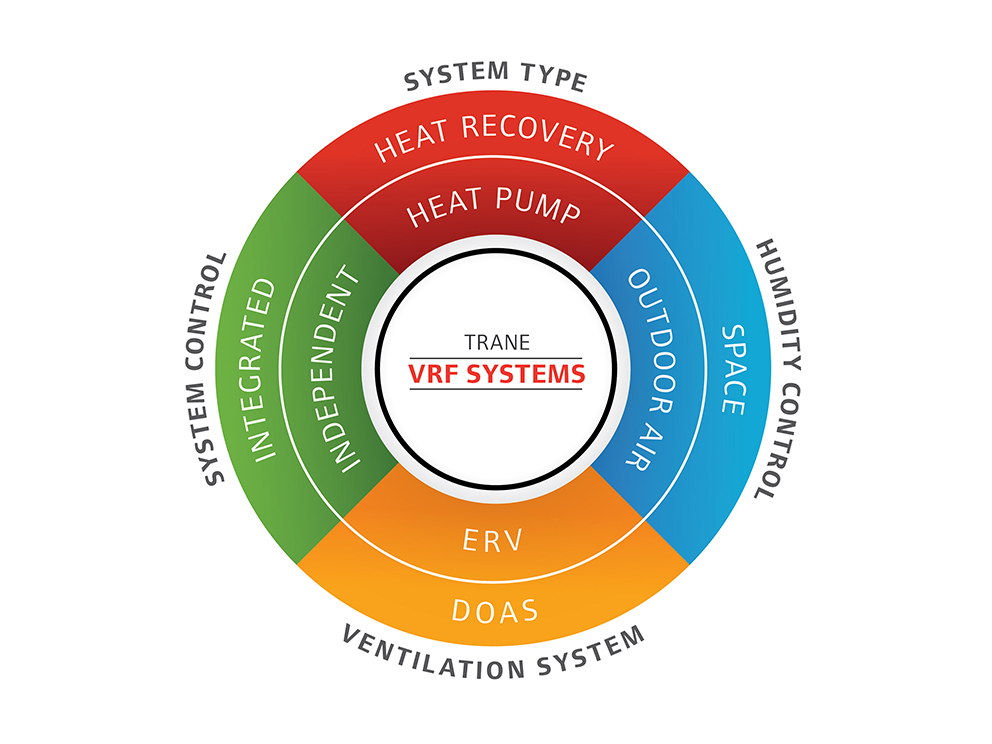

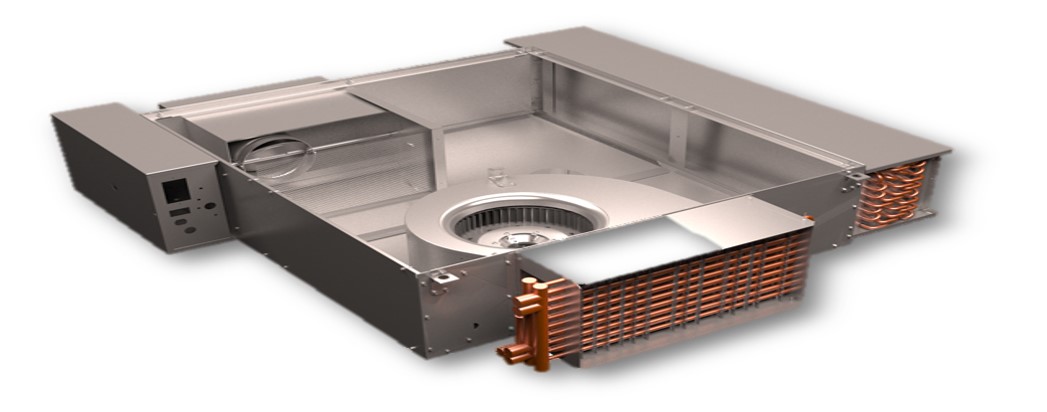

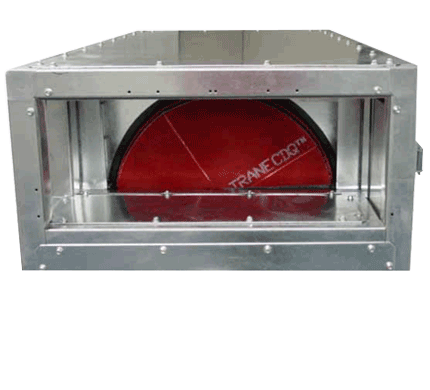

Based on a solid, multi-year relationship and their knowledge of Trane’s experience in creating high performance buildings, Transitions Optical solicited Trane’s advice and assistance for their upgrade project. After reviewing the business case and specific building needs, Trane made recommendations that delivered an immediate 25 percent cost reduction. These included replacing existing chillers with three chillers instead of four as first planned. Trane also recommended integrating all components into a single, energy-efficient system using a Tracer Summit building automation system. To help assure continued high performance, Transitions Optical has a Trane Select Service Agreement that provides a full equipment warranty plus full HVAC equipment and controls maintenance. Trane will repair/replace any faulty equipment, free of charge. The customer benefits through consistent, planned maintenance with no surprises.

Results

The upgrades are generating 144,000 ($192,000 USD) in annual energy savings and have reduced energy needed to produce each lens by 40 percent--from 1200 Watts per lens to 800 Watts per lens. In 2007, cooling costs at the plant represented fifteen percent of overall annual electrical costs. In 2010, cooling costs are only about eight percent of overall electrical costs. Average monthly energy savings are about 60,000 kWh--equivalent to shutting down the entire plant for three days a month and saving 12,000 ($16,050 USD) per month. These savings have a direct, positive impact on the bottom line--and with the environment in mind.

Tim Farrelly, Transitions Optical, said, "This system allows us to use the minimum cooling as required at any given time, 24 hours a day, 365 days a year. Using Trane chiller plant management software, Transitions has had the ability to systematically and safely increase core cooling temperatures over the past two years. Prior to this project, we were running temperatures of three to five degrees Celsius. Now we are running at ten degrees C. The software automatically controls chiller capacity. Prior to this system we were running two or even three chillers most of the year. With Trane controls, we are running one chiller for nine months of the year and a maximum of two chillers during summer months. This has led to a significant cost savings."

About Transitions Optical

Transitions Optical, with headquarters in Florida, owns the Tuam, Ireland, plant. The plant produces the optical industry’s top photochromic lenses -- lenses that darken on exposure to ultraviolet radiation -- for optical manufacturers worldwide. Transitions lenses improve visual comfort and quality by reducing glare and enhancing contrast. They also block 100 percent of harmful UVA and UVB rays to help protect eye health.