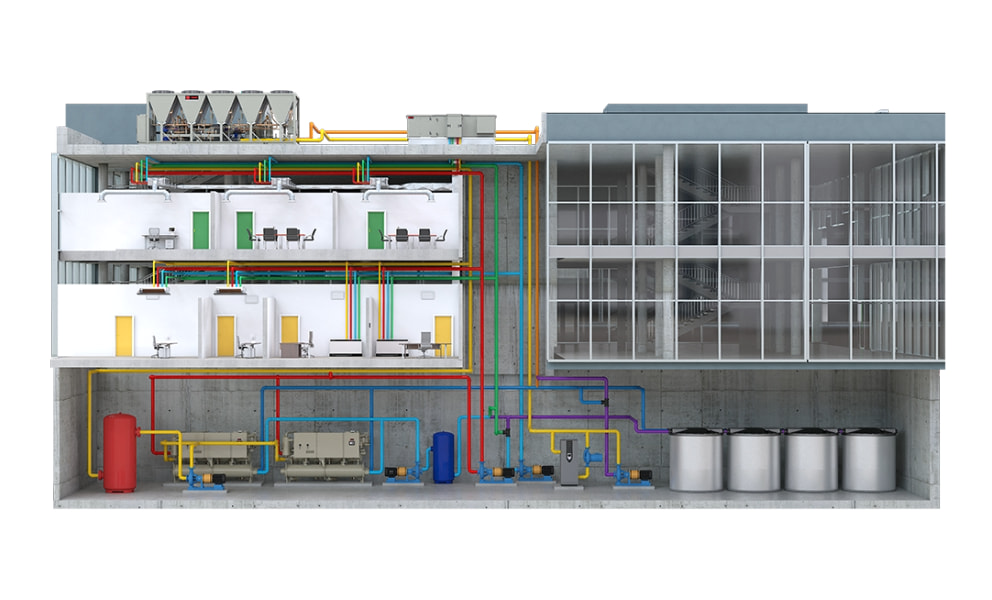

- Air-to-Water Heat Pump (30 to 230 tons; 390 to 2500 MBH) operates in heating or cooling mode. Fluid temps up to 140°F. Heating down to 0°F ambient.

- Water-Cooled Helical Rotary Chiller (80 to 250 tons) operates in heating mode to immediately heat the building; heating capabilities of up to 165° F (74°C).

- Air-cooled Scroll Chiller – Model CGAM (20 to 130 tons) offers efficient cooling and heat recovery production.

- Tracer® Controls applied control sequences balance multiple priorities: reliability, carbon reduction, efficiency and cost savings, during heating, cooling and energy storage.

- Hydronic Branch Conductor Enables adequate heating with a dual-purpose coil at a milder hot water temperature.

- Thermal Energy Storage Tank (20 tons for 8 hours; 2 million BTUs heating) stores reclaimed waste heat in form of cold water for later use.

Pre-engineered Hydronic Heating

Comprehensive Chiller-Heater Systems for Electric Heat Pumps

Pre-engineered Hydronic Heating

Comprehensive Chiller-Heater Systems for Electric Heat Pumps

Achieve cost-effective, energy-efficient, reliable, sustainable cooling and hydronic heating, while reducing carbon emissions.

Comprehensive Chiller-Heater Systems, featuring electric heat pumps, are pre-engineered innovative solutions that make sustainable HVAC easier to specify and implement.

- Combined heat pump chiller, controls, and application knowledge and expertise

- Ideal for larger new and existing buildings, especially those with hydronic systems

- Systems design and controls strategies aimed at enhancing efficiency.

- Allows for redundancy and defrost management to maintain comfort throughout the day

- Multiple options such as thermal energy storage, boiler back-up and defrost management

-

Flexibility

Comprehensive Chiller-Heater Systems can help you meet diverse heat and cooling loads. These flexible systems can be combined with virtually any hydronic heating and cooling solution, with option to address indoor air quality through improved filtration, air cleaning and variable ventilation.

-

Reliability

Comprehensive Chiller-Heater System controls allow you to consistently maintain high performance by managing equipment capabilities and limitations properly to serve changing conditions. It also allows you to design for redundancy and defrost management, as well as to maintain comfort as loads fluctuate throughout the day.

-

High Performance

Exploit dramatic improvements in heat pump heating capabilities to help buildings function better and reduce carbon emissions. Chiller plant controls provide sequencing and advanced optimization strategies that reduce energy use.

-

Sustainability

Become part of the climate solution as utilities produce cleaner electricity. Electrified hydronic heat pump systems can reduce or replace fossil fuels for heating in buildings, cutting down on direct carbon emissions.

-

Compliance

Cleaner electricity generation: fuel transformation for building electrification can help meet tighter regulatory requirements, avoid carbon penalties and achieve sustainability goals.

System Applications

Explore our Comprehensive Chiller-Heater System Types

We offer multiple options and variations so that more buildings in more places can maintain year-round comfort while working to reach their decarbonization goals.

Base System

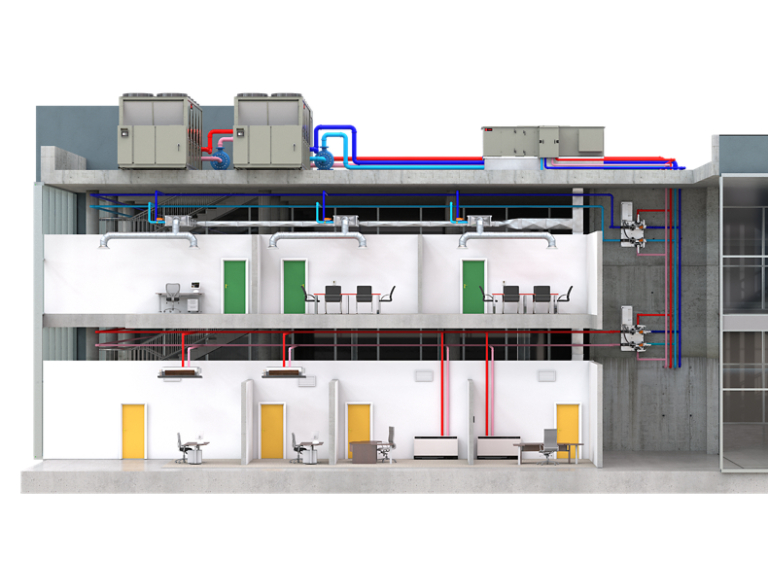

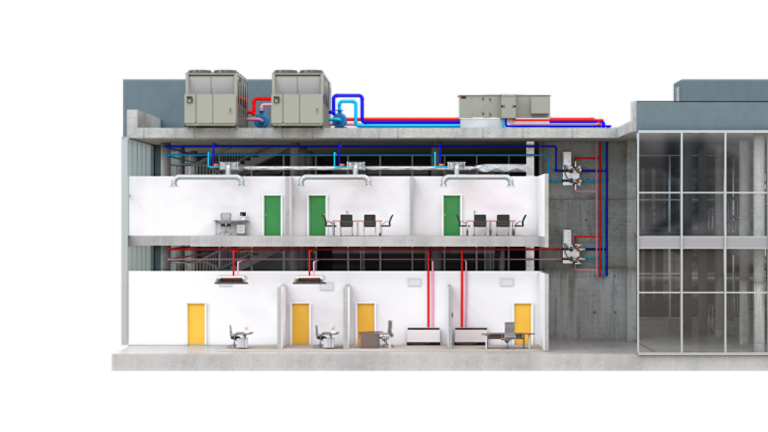

Air-to-Water Heat Pump System

The base System features advancements in air-to-water heat pumps to meet lower ambient temperatures. This electrified system works with many existing hydronic airside systems, offering configurations and options to fit a variety of applications

Product Literature

Application Guides

-

Comprehensive Chiller-Heater System Application Guide

SYS-APG003*-EN

-

4MB

Brochures

-

Comprehensive Chiller-Heater System Brochure

SYS-SLB033-EN_06282022

-

Thermal Battery Storage Source Heat Pump System Brochure

SYS-SLB035-EN

Case Studies and Newsletters

Sustainability Now Within Reach

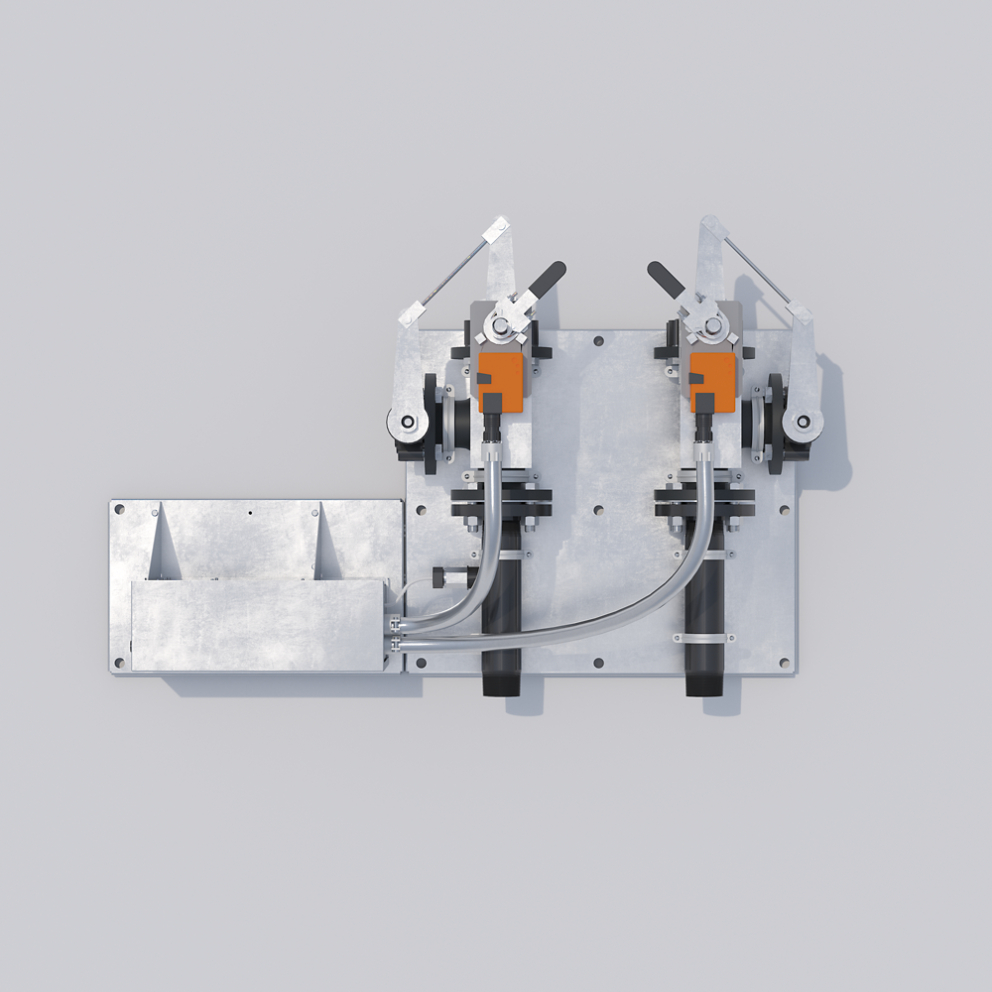

Make your electrification of heat a no brainer by simplifying and reducing installations costs of hydronic heating systems using the new Hydronic Branch Conductor.

Video

Ice Heating: Reimagine Electric Heating

Frequently Asked Questions

A chiller-heater system integrates heat pumps, chiller-heaters, and other hydronic distribution components to provide reliable, energy-efficient, and low-carbon cooling and heating for buildings with hydronic systems. These pre-engineered systems simplify the implementation of electrified HVAC solutions, offering customizable options to meet specific climate and hot water temperature requirements while efficiently managing heat recovery.

The system works by utilizing heat pumps and chiller-heaters machines that are controlled by a building automation system to provide reliable heating and cooling year-round. During colder months, heat pumps transfer heat from the cold outdoor air or recover heat from inside the building to meet the heating loads. In warmer months, the system rejects heat from the building to cool occupants. Additionally, some system variations include thermal energy storage, which allows for the system to store reclaimed energy for when its needed, and a cascade water-to-water heat pump option to boost hot water temperatures to meet the higher heating temperature requirements.

Chiller-Heater Systems apply heat pump equipment and control knowledge to provide cost-effective, energy-efficient cooling and heating for larger buildings, reducing carbon emissions and supporting decarbonization goals.

Thermal energy storage works by storing excess thermal energy collected by the heat pump or reclaimed from the building for use during peak demands. This is achieved through the use of insulated ice tanks called Thermal Battery storage and uses water as a phase change material in order to maximize the energy storage capacity of the tanks.

Chiller-heater systems can be integrated into both new and existing buildings, but the heating temperatures requirements of the existing system need to be evaluated. To assist with retrofit applications, the Hydronic Branch Conductor can be utilized with existing building infrastructure in order to reduce installation costs and minimize disruption. The Conductor efficiently distributes heated or cooled water to dual purpose building coils and maximizes heat pump system efficiency. Additionally, it simplifies the installation process and provides better control and zoning, making the retrofit more affordable and enhancing occupant comfort.