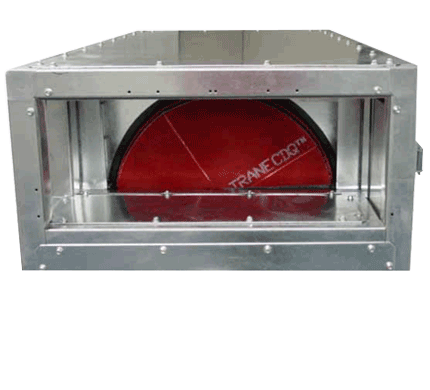

CALMAC® Plate Heat Exchanger

CALMAC® Plate Heat Exchanger

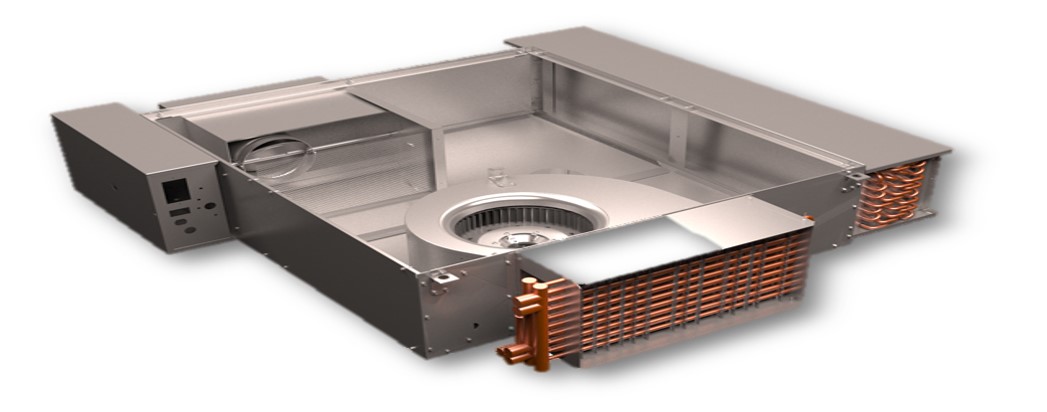

Key Features:

- Exclusive plate-locking system keeps plates aligned and tightly

- sealed even at high working pressures.

- Rugged roller assembly reduces wear, facilitates easy service access

- Standard Protective Shroud is OSHA-Compliant

- Bolted construction for strength and accessibility

- Robust frame heads construction eliminates need for reinforcements, facilitates easy maintenance

- Standard acrylic resin coating system ensures maximum protection from corrosion

- Standard studded, threaded or flanged port options

Optimal Performance and Protection

You may need your HVAC systems to carefully transfer thermal energy between two dissimilar fluids. Our units are well-suited to applications where cross contamination is a critical concern.

Great for a Variety of Applications

Plate heat exchangers work for a variety of uses including: Thermal energy storage, Pressure Interceptor, District Heating and Cooling, Water Source Heat Pumps, Tower Isolation, Boiler Blowdown Heat Recovery, Free Cooling/Chiller Bypass, Swimming Pool Heating, Geothermal Heating and Greenhouse Heating.

Plate Heat Exchanger

See more advantages below.

Achieve superior performance

CALMAC Plate Heat Exchanger comes in broad range of plate configurations to help deliver maximum economy and superior performance for any size application including several plate sizes for each connection size. In addition, plates are pressed in the patterns that are best suited to optimizing the performance of your system. By combining the right plate geometry, patterns and connections you get a customized heat exchanger to achieve a design that is ideal for your application.

Optimize your thermal energy storage system

A thermal energy storage system, using the CALMAC plate heat

exchanger with logic programmable digital controls, sensors and

control valves, can modulate the rate of ice discharge so as to ensure

that a sufficient amount of ice is available during the “peak

electricity demand” period. Plus, our plate heat exchangers can

separate glycol in the storage loop from water in the building

distribution loop -- without adding energy to the process.

Access your equipment with greater ease

Since connections are usually made to the front of the unit, piping can stay in place when the unit is opened, and all of the components can be removed within the length of the frame, minimizing downtime. Simply loosen the compression bolts and add the plates you need. And worry less about cleaning. The plate’s uniform flow and high fluid turbulence provides continual scrubbing action reducing fouling and eliminating the need for frequent cleanings. While low media holdup also allows for easy drainage.