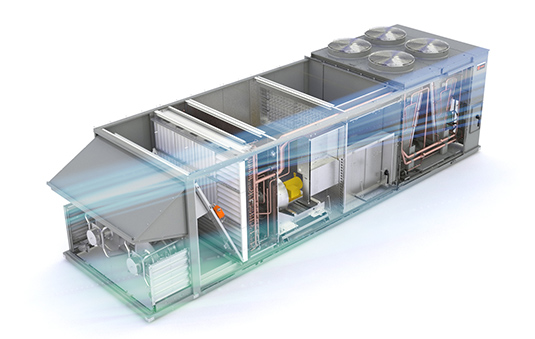

IntelliPak® Rooftop System with Symbio™ 800 Connected Controls

April 12, 2018

Five Questions with Charles Abbinanti – Product Manager, IntelliPak®, about the recent commercial rooftop Intellipak release

We talked to Charles Abbinanti, Product Manager for Trane® large commercial rooftop equipment, to ask him what’s in store for the latest product release, that was announced in early April. What’s new? What’s improved? And how Is Intellipak maximizing outcomes for our customers? Read on.

1. How did you decide what to build for the latest release of IntelliPak?

Charles: The process for redesigning the industry leading IntelliPak started with the customer. We kicked off the process by conducting interviews with key customers and stakeholders in eight of the largest geographic markets. During these interviews we learned about customer requirements and industry trends. We frequently verified our learnings by reviewing our design and prototype with a diverse customer panel. Beyond the voice of the customer, we studied industry regulations and trends in new technology to make sure we are supporting the future needs of our customers. For example, all units leave the factory with connected capability while both the refrigeration and heating components already meet 2023 regulatory requirements.

2. The next generation IntelliPak with Symbio 800 has an IEER rating up to 17.8. How was that achieved?

Charles: During our customer interviews we learned that energy conservation will continue to be a key requirement when selecting an HVAC provider with energy costs, regulations and environmental sustainability commitments driving the need for improved energy efficiency. With this launch, the IntelliPak will continue to lead the large roof top market in energy efficiency. The engineering team optimized the refrigeration system to match the customer’s actual performance requirements, improving energy efficiency with the use of variable speed compressors, direct drive plenum fans and control algorithms. The IntelliPak with Symbio 800 is the only large rooftop solution that can meet the Consortium for Energy Efficiency advanced tier for both EER and IEER at each tonnage. In addition to product performance, the customer can optimize building energy performance during the system selection process by leveraging the integration of Trace® 3D plus and Trane’s unit selection tool.

3. How does the new Symbio 800 controller increase the capability of the IntelliPak?

Charles: The Symbio 800 controller significantly impacts all aspects of the customer experience. First, the field programmable capability with expansion hardware provides greater flexibility during the equipment selection process. Next, installation—specifically controls integration--has been simplified. The new controller can support additional communication protocol and a unit specific points list will be given to the customer. After installation, the Adaptive Controls™ improve the performance of the unit by helping avoid potential disruptions during rapidly changing conditions. Finally, the connected capability of Symbio 800 and the significantly improved diagnostics enable a customer to monitor and analyze performance data to ensure the unit is operating to the design specification.

4. There was a 60% reduction in wiring in the new unit. How was that achieved and how does that improve outcomes?

Charles: With the launch of the IntelliPak with Symbio 800 we are committed to maximizing our customer’s outcome with minimal energy throughout the entire product lifecycle. Industry leading quality and reliability is an essential requirement for achieving this goal. The project team made quality the number one deliverable and spent over 100K hours testing the design and validating system performance. The engineering and manufacturing teams worked concurrently to build quality into both the product and assembly process. As an example, the new product uses 60% less wiring connections and wire length has been reduced by a half mile. The team achieved this improvement by leveraging the intelligent control components found in Trane chillers and optimizing the location of wiring components throughout the unit.

5. Can you talk about the impact for owners and facility managers?

Charles: The entire rooftop system was designed with the customer’s experience in mind. We want to support owners and facility managers by developing an HVAC system that will consistently operate to the design specification. We started this process by adding Adaptive Controls™ that enables a larger operating range for the unit to provide cooling and will automatically adjust to keep the unit online. Next, we wanted to provide customers with a way of validating the performance of the HVAC system. We now offer a factory installed Power Meter and improved performance analytics through our Intelligent Services platforms. This reduces the time required to maintain the unit we significantly improved the diagnostics. For example, the pressure transducers enable the reading of refrigerant pressure through the building automation system and eliminates the need to climb up to the roof and attach gauges to the unit. Additionally, the fans have built in redundancy and do not have any belts or sheaves to maintain. Dual direct drive supply fans are standard and each motor has its own VFD.

To learn more about the features of the new IntelliPak, visit our product page