Whitepaper

Published: July 25, 2023

Meeting New Industry Standards with Rooftop Systems and Intelligent Controls

Can rooftop units still provide the performance that customers need when expectations are so much higher? Can engineers meet those needs and deliver engineering excellence without getting bogged down in complexity? Absolutely. By bringing equipment and controls together from the beginning, you can deliver intelligent rooftop systems.

Quick Facts

- Products

- Tracer SC+ • Equipment Controls • Zoned Rooftop Systems • Packaged Rooftop Solutions • Rooftop Units • Trane® Design Assist™ • Precedent® Rooftop Units • Air-Fi® Wireless Communications • Tracer® Building Automation Systems

- Topics

- Optimal Comfort • Indoor Air Quality • Decarbonization • Energy Efficiency

Packaged rooftop units have been the industry go-to for simple and reliable comfort in a wide range of commercial buildings. However, in today’s world, many rooftop HVAC projects don’t feel so simple anymore.

Industry regulations are more demanding. ASHRAE® 90.1 energy efficiency standard is more stringent. During the pandemic, attention to indoor air quality was heightened. Plus, every client has different expectations for how their building will perform, creating more design and applications challenges to account for.

Expert support and online tools are making it easier for engineers to meet industry regulations while serving more customized customer needs.

Rooftop unit manufacturers have been updating products to deliver the higher performance today’s market is demanding. But equipment only delivers the performance that controls command... leading to the introduction of ASHRAE® Guideline 36, High Performance Sequences of Operation for HVAC Systems. This “how to” for best practice controls programming requires expertise that can be difficult to find.

Packaging the performance that each customer requests.

But guess what? The pressure isn’t all on you. Trane’s newest approach merges our mechanical knowledge and programming expertise to deliver state-of-the-art equipment and controls together in packaged solutions. The resulting “intelligent systems” are pre-programmed to match customer priorities whether that means energy efficiency, indoor air quality, flexible comfort or something else. Usually, it becomes a balancing act to serve multiple KPIs.

Other OEMs are approaching today’s higher performance requirements in a variety of ways. In Trane’s quest to keep it simple for engineers, we wrangled the complexities into an easy three-step process.

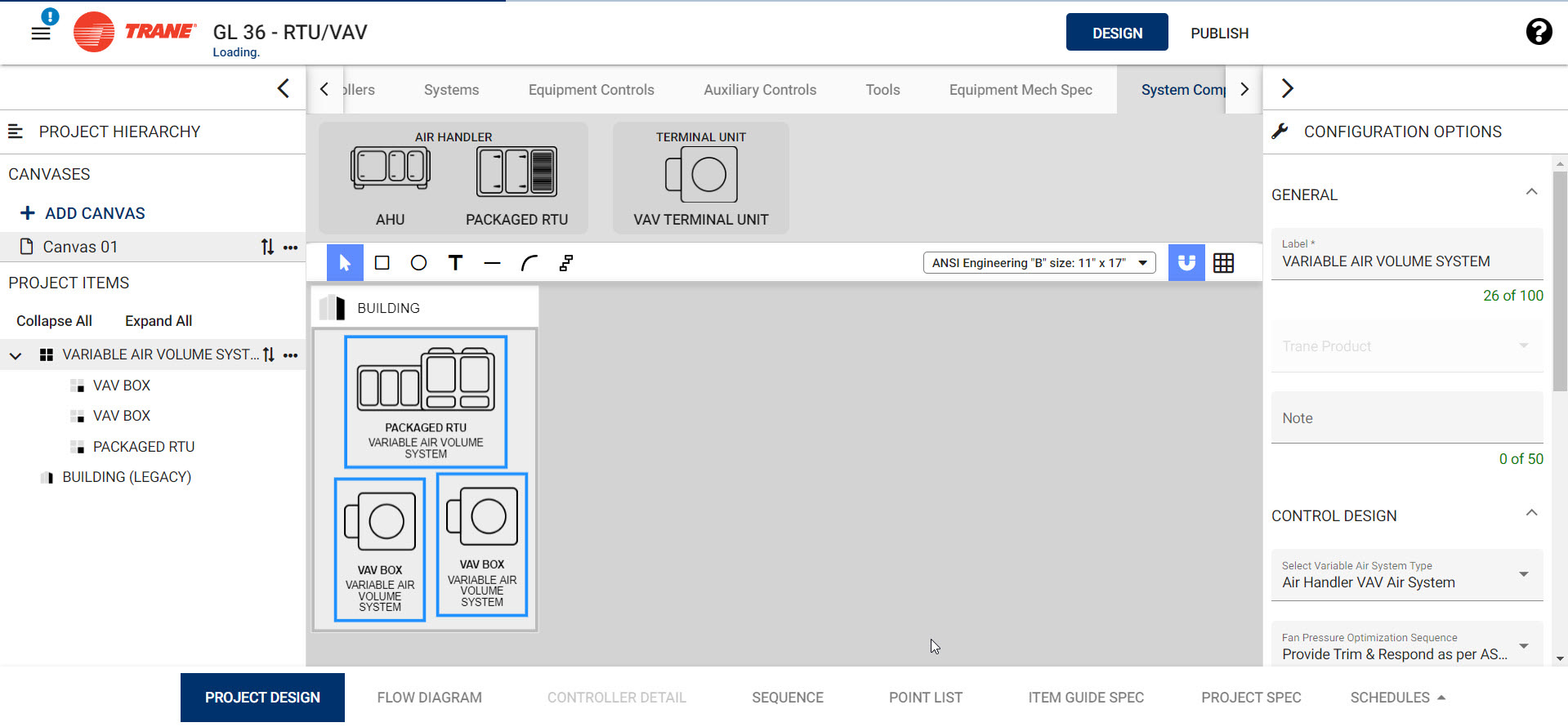

- An online tool called Trane® Design Assist™ guides engineers through control system specification and performance definitions.

- From the factory Trane’s system control applications allow the easy implementation of ASHRAE Guideline 36 appropriate sequences to meet the engineer’s specified requirements.

- The end-customer/building owner receives a performance-built system that operates according to the defined specifications, with the intelligence to sustain that performance over time.

It’s fast, easy, and virtually risk free. The performance you specify comes together in a matter of minutes. With multiple add-ons available for ventilation, filtration, VAV, heat-pump heating and more, intelligent rooftop systems can rival applied systems for overall performance and flexibility—and the software holds the responsibility for most of the complicated, time-consuming, risk-inducing technical work.

Use Trane Design Assist to plan your next project. Get started today at tranedesignassist.com.

Solving for what matters.

Intelligent rooftop systems are the answer to new expectations that demand more rigor from HVAC. Here are some of the current trends that are making equipment/controls synergies even more important today.

Trane has introduced new rooftop products with optional features and optimization programming that bring projects into compliance. All rooftop units meet or exceed current standards. Our large commercial rooftop tiered offering allows you to select units that exceed the minimum IEER efficiency requirements by 11% up to 30%. In the light commercial offering, Precedent® eFlex™ efficiencies are up to 85% higher than standards established by the Department of Energy and ASHRAE.

New energy efficiency standards. Once again, the bar has been raised. This time it’s all about meeting U.S. Department of Energy regulations. The new 2023 system cooling efficiency minimums increased on commercial units above 65K BTU by approximately 15%. Natural gas heating efficiency (> 225,000 btu/h) increased from 80% to 81% steady state efficiency.

Decarbonization. Conventional fossil fuel heating methods are falling out of favor in many parts of the world. More building owners are striving for carbon-neutral buildings to meet local mandates or sustainability goals. Low- and no-cost control methods, like scheduling and optimization strategies, can be deployed in existing building automation systems as first steps in the decarbonization journey. Simple changes can increase the overall energy efficiency of the building and, therefore, reduce its carbon emissions. The money saved by spending less on energy can be funneled into capital projects (such as upgrading to more energy-efficient equipment) to take decarbonization further.

Optimized indoor air quality. The public became more sophisticated about indoor air quality (IAQ) during the COVID-19 pandemic, changing expectations for commercial buildings forever. Increasing ventilation and filtration can help to optimize indoor air quality, but it results in higher energy use and operating costs, too. Some rooftop systems offer a range of filtration options, including MERV 13 and higher. Applying the right control sequences can minimize the potential cost consequences that may be necessary to achieve higher IAQ.

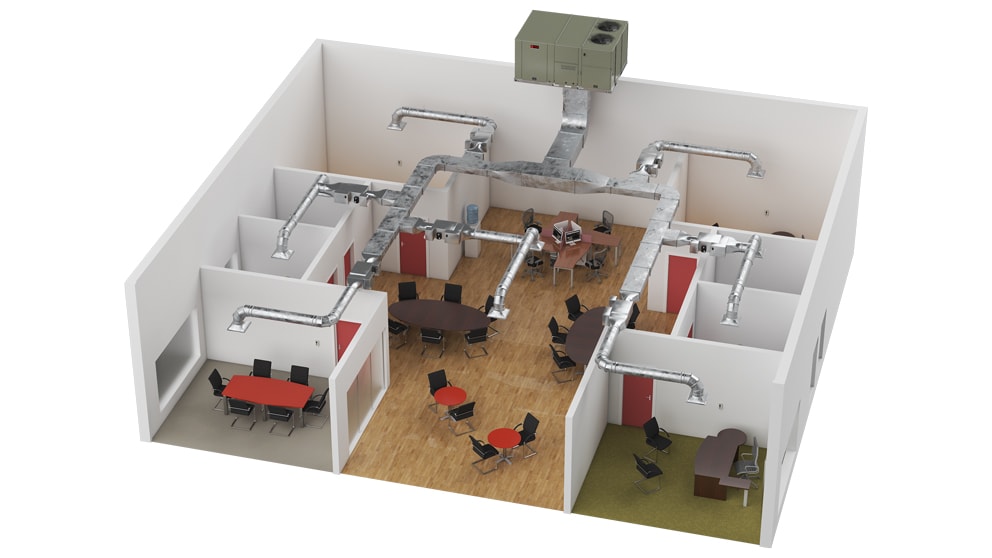

Improved occupant comfort. Zoned rooftop systems are an improved way to deliver more targeted comfort control in spaces like health care facilities, schools and office buildings. Zoned systems inherently require more sophisticated controls—intelligent systems include features that simplify installation, commissioning and service while maintaining performance parameters continuously.

Contractor and service provider challenges. With experienced technicians retiring and new skilled employees scarce, contractors want to keep projects simple and fast. Packaged rooftop units feel familiar. Packaged rooftop systems ease the transition to the more complicated solutions the market is demanding. Next-generation controls make system setup, service and maintenance as easy as ever, with digital interfaces and mobile apps that make sense to a younger workforce.

Packaged components are better together.

So, what goes into an intelligent rooftop system? With Trane, everything that is required for you to meet customers’ performance expectations can be included in the package. We have a complete portfolio of rooftop units with performance features and options; controls from unit controllers to building automation; and a service portfolio that spans from installation and commissioning through ongoing performance support. Power meters, valves, actuators, equipment and BAS can typically be integrated, too. Building everything on open, standard protocols allows for multi-vendor installations and easy connectivity throughout the building ecosystem.

As a starting point, a typical basic system includes the rooftop unit, VAV terminal units, system controls wireless sensors.

Rooftop System Essentials

Packaged rooftop units have factory-mounted controls, and we can factory-assemble a wide range of options for managing temperature, humidity, ventilation and indoor air quality to serve almost any specification (gas packs, heat pumps and hybrid dual fuel systems). Optional features include variable speed fans and compressors, modulating hot gas reheat, modulating gas heat, high MERV filtration, and many more.

| Features | System Benefits |

|---|---|

| Higher Efficiency Units | Energy Savings |

| Multi-Speed or Variable Speed Fans | Quieter - Fan Energy Savings |

| Better Humidity Controls | More Comfortable Spaces |

| Modulating Gas/Electric Heat | Mitigates Overheating in Off-Peak Conditions |

| Heat Pumps/Dual Fuel | Lower Carbon Emission Systems |

| Integrated Modern Controls | Secure, Remote Connection, More Serviceability |

Heat pump options: All-electric or dual fuel

The electrification of heat is an important tactic in an overall building decarbonization strategy. Many rooftop units can reverse the refrigeration system to operate as a heat pump—delivering all-electric, all-in-one cooling and heating. Some units can be fitted with a separate gas heater with greater turndown, a hot-water coil with modulating valve, or a modulating (SCR) electric heater.

Some customers, particularly those in colder climates, may be hesitant to go all-in on electric heating. Similar to hybrid cars that provide the reassurance of a combustion-engine “plan B,” hybrid dual-fuel rooftop systems include a supplementary gas heating system. They operate primarily using the heat pump for electrified heating. Gas heating kicks in only as needed with an adjustable changeover temperature range from 45°F to 15°F. In many cases, the biggest benefit to the customer is peace of mind. Building operators are often surprised by how infrequently gas heating actually gets used.

Building automation and system controls provide the necessary coordination and management of all the system components in a manner that delivers (and maintains) your specified performance. Building automation systems orchestrate equipment performance using pre-engineered applications that can be altered for each project—simplifying the delivery of the engineering design, assuring the deployment of industry standards and enabling greater consistency across multiple buildings. Unlike other controls that are “capable of” delivering specific criteria, Trane definitively states that our controls “will deliver” the promised performance. It’s a big difference, and it provides added reassurance that engineers’ solutions will provide energy efficiency, comfort and other benefits as promised.

Latest-generation unit controls arrive onsite with factory-programmed optimized sequences and prepped for app-based remote management. Advanced unit controllers allow for greater flexibility in set points, and capably manage complex equipment setups to deliver more advanced benefits for energy efficiency/sustainability, humidity management, zoned comfort and indoor air quality. Digital controls can produce multiple data points to serve detailed analytics. Intuitive user interfaces at the unit and on the mobile app allow building operators to detect declining performance easily and early to prevent downtime and correct cost inefficiencies. Built on open standard protocols, these controllers easily integrate with any non-proprietary building automation system.

Wireless zone sensors support open communication protocols through conformance with ASHRAE Standard 135 (BACnet/ ZigBee®). Depending on the application, sensing may be required for temperature, humidity, occupancy and CO2. Air-Fi® Wireless sensors feed into the BAS for easy management and control. Wire-free communication means sensors can be removed and relocated to serve future needs, without an electrician and without damaging walls

Common System Configurations

Single-zone, two-speed system—This simple system is well-known to many industry professionals and building owners. It is comprised of a single rooftop unit with controller, and at least one zone temperature sensor or thermostat. The supply fan operates at either high or low speed, depending on cooling or heating requirements. Manifolded scroll compressors provide cooling, while heating is provided by a gas or electric heater. The unit may also be configured to reverse the refrigeration system to operate as a heat pump.

Single-zone VAV system—This unit’s supply fan varies its speed to provide a variable volume of conditioned air to the zone. Manifolded or variable speed compressors provide cooling, while heating is provided by a gas or electric heater, or by reversing the refrigeration system to operate as a heat pump. This type of system is ideal for large open spaces such as auditoriums, warehouses and open retail.

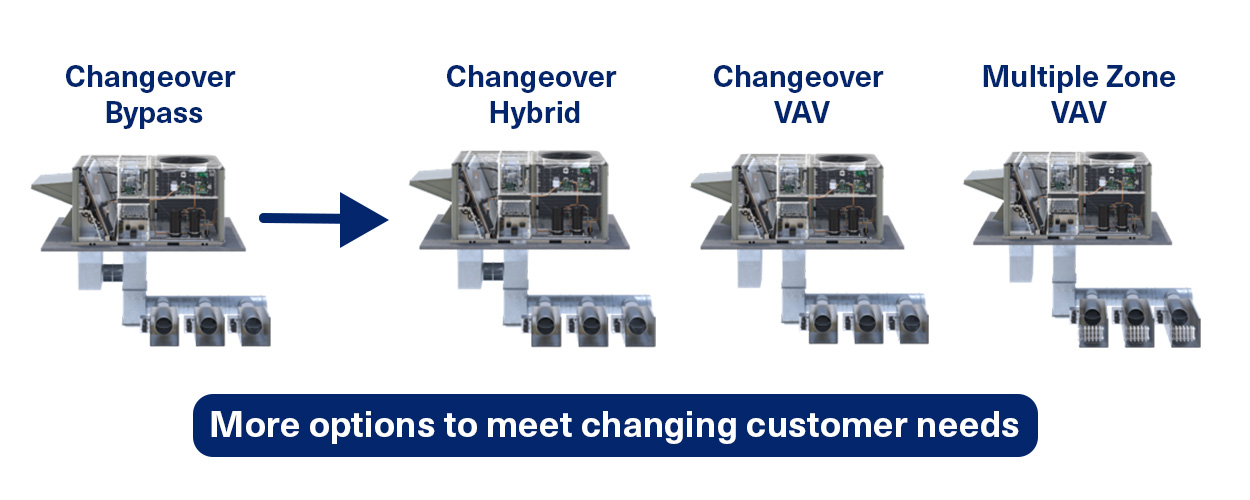

Changeover hybrid system—Comprised of a single rooftop unit with controller, two or more VAV terminal units (each with a controller and a zone temperature sensor) and a bypass damper. Manifolded scroll compressors provide cooling, while heating is provided by a staged gas or electric heater, or by reversing the refrigeration cycle to operate as a heat pump. The system control panel uses a voting strategy to determine whether the rooftop unit should deliver cool air down the duct or “changeover” to deliver warm air. A variable-speed fan varies the supply of cool air to the zones as the zone-level VAV dampers modulate (bypass damper is closed), and then operates at full speed in heating mode, thus requiring the bypass damper to bypass excess supply air to the returnair path. This highly diverse system is suitable for many applications and delivers greater energy efficiency than older changeover bypass systems that used a constant-speed supply fan.

Changeover VAV system—A single rooftop unit with controller, combined with two or more VAV terminal units, each with a controller and zone temperature sensor. Manifolded or variable-speed compressors provide cooling, while heating is provided by a modulating gas or electric heater. Again, the system control panel uses a voting strategy to determine whether the rooftop unit should deliver cool or warm air down the duct. As the zone-level VAV dampers modulate, the variable-speed fan varies the supply of air during both cooling and heating operation; therefore, a bypass damper is typically not needed.

Multiple-zone VAV system with terminal electric or hot water heat— In this configuration, one rooftop unit can serve several zones with independent temperature control in each one. It is capable of simultaneously providing heating to some zones and cooling to others. Most of the VAV terminal units are equipped with electric or hot-water heat.

A knowledgeable system expert can tell you more, and help you weigh the pros and cons of each one for a particular application.

Controlling for operational excellence

Most providers’ systems are “capable of” operational excellence. Trane takes the responsibility for making it happen and makes it easier for building owners to sustain the benefits over time. Complex systems require more complicated programming, and Trane brings this in-house to optimize performance using our library of documented engineered solutions. Most installations will require minor customization to achieve situational optimization, but the essential performance arrives readymade within Trane’s Symbio® equipment controls and Tracer® building automation system. Standardized, graphical interfaces provide user simplicity that helps reduce user errors that cause performance to decline over time. It’s a more professional and risk-free approach than putting important programming in the hands of technicians with wide-ranging skillsets.

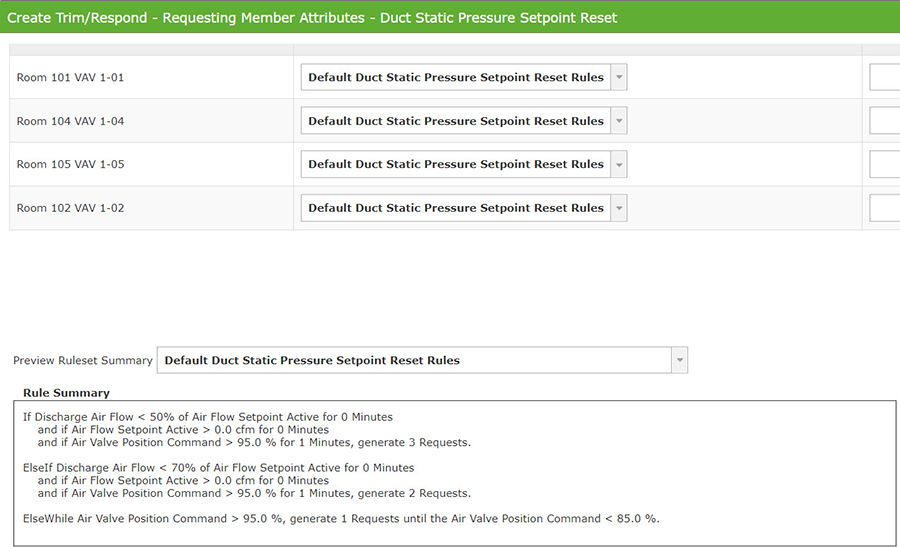

Trane® Tracer systems have been developed to deliver ASHRAE Guideline 36 sequences and performance. Our pre-engineered trim-and-respond application includes the ASHRAE GL 36 defined rules, allowing flexibility to modify or expand the rules to meet any building or system need.

Optimization: Understanding what it really means.

Optimization may be one of the most frequently stated benefits in our industry. But what does it really mean? Essentially, it is the act of making a system as effective as possible in delivering the benefits a customer wants. It’s a bit of a balancing act, and there are almost always tradeoffs.

For example, running fans constantly to improve ventilation and indoor air quality often comes with a penalty to energy efficiency. Simply changing temperature settings to save energy and decarbonize is an obvious threat to occupant comfort. Optimized controls can operate the system to achieve multiple goals in prioritized, varying degrees.

- Schools may prioritize indoor air quality to improve test scores and attendance.

- Restaurants may prioritize kitchen humidity management to maintain a comfortable work environment that helps to retain top talent

- Offices may want zone control that supports individualized employee comfort

Trane removes the need to begin each programming project from scratch. Our engineered solutions are updated often to reflect current standards, guidelines and security practices. Once installed, systems that are cloud-connected will remain up to date and secure through available continuous commissioning that restores the original settings and updates applications when new best practices are discovered, or different requirements come into play. Controls also enable the extended system monitoring that is a requirement for many building certifications, including WELL® and LEED®.

Right-Sized System Control

Not every building requires the comprehensive capabilities of Tracer® SC+ system controls. For many buildings that use packaged rooftop systems, Tracer Concierge® provides scaled-down system management that’s simple and effective—and perfect for buildings without a facility professional on staff. It’s easy for contractors to install, set up and service, too.

Raising energy efficiency through a systems approach.

Comprehensive system integration makes it much easier for operators to match system use to building occupancy and avoid using more energy than is necessary. Trane unit controls integrate easily with any building automation system into an overall energy management approach. That’s critical to lowering a building’s carbon impact. State-of-the-art building automation systems can reduce energy consumption in commercial buildings by up to 40%.

Even as a standalone system, intelligent rooftop systems are delivering significant energy savings that have been documented in multiple studies. Our own modeling demonstrated 9% energy savings over ASHRAE 90.1 baselines, with 23% savings compared to a “typical building.”

A Pacific Northwest National Lab Study found 29% energy savings vs. poorly running/unoptimized buildings.

Making your good work even better.

Rooftop systems will probably get even more complex as industry pressures increase. Right now, you can meet virtually any performance requirement by pairing packaged rooftop systems’ features and options with pre-engineered controls. The end goal is to make it easier for you to deliver engineering excellence to serve any customer’s needs.

Engineered excellence without complexity. Trane gives you an easy path into the future with higher-performing intelligent rooftop systems.