Do you know what downtime is REALLY costing you?

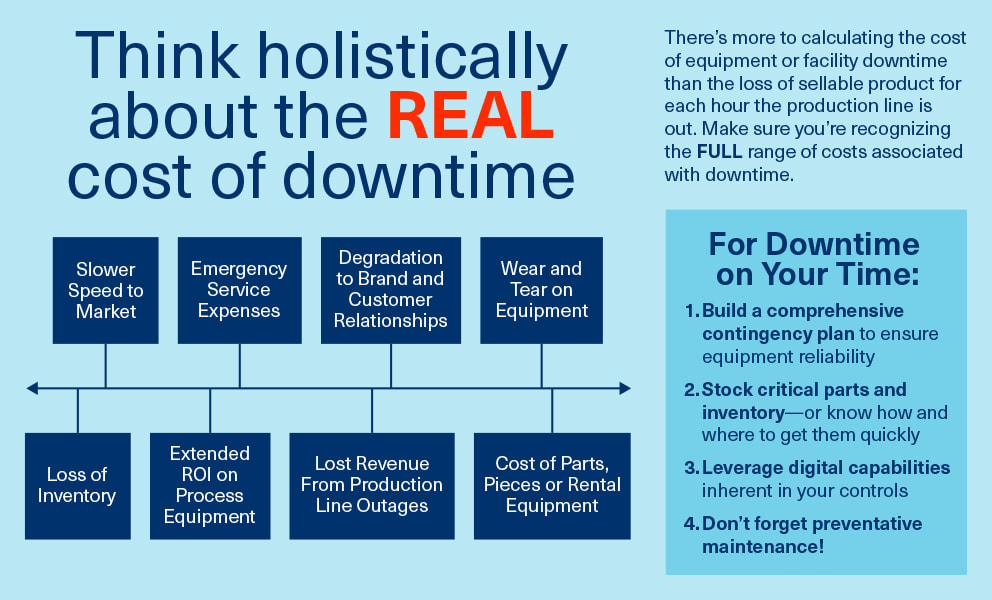

When talking with manufacturers about the potential costs of downtime, we regularly hear that it is difficult to quantify all the components that factor into the true cost of downtime. There are three obvious costs that most companies consider and can easily calculate:

- Loss of revenue if production lines go down and/or lost inventory when product needs to be remade. A line that is not running is not making money—this can be as much as 6 to 7 figures of lost revenue for every day the line is down. But even when all your lines are running, variance in the ambient conditions can render product unusable. In the production of gel caps, for example, the margin for error in managing the ambient manufacturing conditions is laser thin—so the slightest variation may cause product spoilage and lost inventory. Or, in a bottling company, where the plastic bottles cannot be filled until they’re adequately cooled—if there is a breakdown in that cooling process, inventory production halts entirely.

- Emergency service expenses associated with the cost of getting a technician to service the product. If the equipment fails on an evening or weekend, higher service rates may apply. In addition, the technician you get on short notice may or may not know your facility or equipment and may therefore take a longer time to solve the problem.

- Cost of parts, pieces or rental equipment for equipment that is unfixable on the spot. New parts may need to be ordered and rental equipment may be required for interim production to resume. And rush shipping charges may be incurred if the correct parts are not on hand.

Many rely on totaling the invoices received (from service, parts or rentals, new equipment, etc.) and combining that with the market value of their production line capacity and output—and the corresponding loss in sellable product for each hour the line is down. But, in reality, many other costs come into play when downtime occurs.

A true calculation of downtime costs should include the following:

- Wear and tear on equipment when the failure occurs. This may affect not only the failed part or piece of equipment, but also to other related equipment in the process. In some environments, large motors and control rooms need to be cooled in very specific ways. If those spaces can’t be properly cooled, the entire system may need to be shut down—causing additional system stress as everything is ramped back up again.

- Opportunity cost of slower speed to market. If product isn’t getting into the market, profits will be sacrificed. In the electric vehicle (EV) industry, for example, speed to market represents a huge competitive advantage. Your product must be available for customers to buy it. The race to be “first” with any electric vehicle type is the difference between leading or being a fast follower.

- Slower ROI on process equipment, particularly for higher cost, higher tech capital equipment purchases. Increased downtime and lower production means that the timeline to break-even on your capital investments will be extended.

- Degradation to brand, reputation, and customer relationships. Perceptions of your ability to deliver products on time and with high quality may suffer. For niche manufacturers, selling to just a few big players, like most in the pharmaceutical industry, one “bad job” can be detrimental.

So, rather than doing a post-game review of the real cost of downtime how can you optimize your ability to maximize uptime?

1. Build a comprehensive contingency plan that ensures reliability in your equipment and processes to avoid costly downtime. This includes knowing your rental partner before your equipment goes down and knowing how you will tap into power, water, valves, etc. It should also include any critical plant floor diagrams, key information on controls strategies and schedules and any other pertinent information necessary for the team who will get you up and running again. With a robust fleet of technicians and equipment stationed throughout the country and decades of experience deploying temporary OEM HVAC solutions, Trane Rental Services can help you build a comprehensive contingency plan and quickly execute it when equipment fails or for planned maintenance.

2. Stock critical parts and inventory. Or know how and where to get them quickly in case of emergency. This will help avert supply chain challenges that may arise when a critical part is needed urgently. Knowing when and where to build redundancies into your processes and equipment can also help avoid major problems. Our thorough rental services analysis will ensure you’re covered.

3. Leverage the digital capabilities inherent in your controls. Use of digital controls can provide real-time data to help monitor ambient conditions and the health of equipment throughout your facilities. Using digital models and AI can help you anticipate problems before they arise – and address future failures before they cause downtime.

4. Don’t forget preventive maintenance. The plan should include strategies for regular, preventive maintenance so crises can be avoided altogether. If you know a piece of equipment is likely to fail in a certain month, you can schedule minor maintenance the month before you might otherwise have a major incident on your hands. Your Trane rental contingency plan will address this scenario. Also, moving to a more predictive maintenance model that leverages cloud data, software and analytics tools can help continuously monitor your facility to be able to spot issues before they become major problems—letting you manage “downtime on your time”. Trane’s rental equipment comes with remote digital monitoring capabilities to give you transparent insight into your equipment and allow our engineering team 24/7 insight to intervene before downtime becomes primetime.

Many factors need to be considered to minimize downtime, and it’s important to have contingency plans that are updated for current market conditions, technological advances and new industry best practices.

Trane is a trusted advisor who can help you plan for the entire lifecycle of your equipment and facilities. In addition to our robust rental engineering and equipment offerings, we are with you on your journey to advise on all elements of your facilities: equipment sales and ongoing service, controls and monitoring, predictive maintenance, data and analytics support, and our unmatched network of equipment and service providers. No matter where you are on your journey, let’s get started!