How Standard Work and Pre-Engineered Systems Can Improve the Reliability of Chiller Plants

February 02, 2022

Often, a central chilled water plant can be one of the most critical systems within a facility, especially during facility operations—so wouldn’t it be logical for the design and installation of these plants be considered critical as well?

Expecting a central plant to be reliable is a given, so it makes sense that the steps leading up to the startup of that first compressor be as reliable as possible, too. Putting standard work practices, pre-engineered sequences and documentation into place can go a long way in helping to ensure the reliability of the chilled water plant.

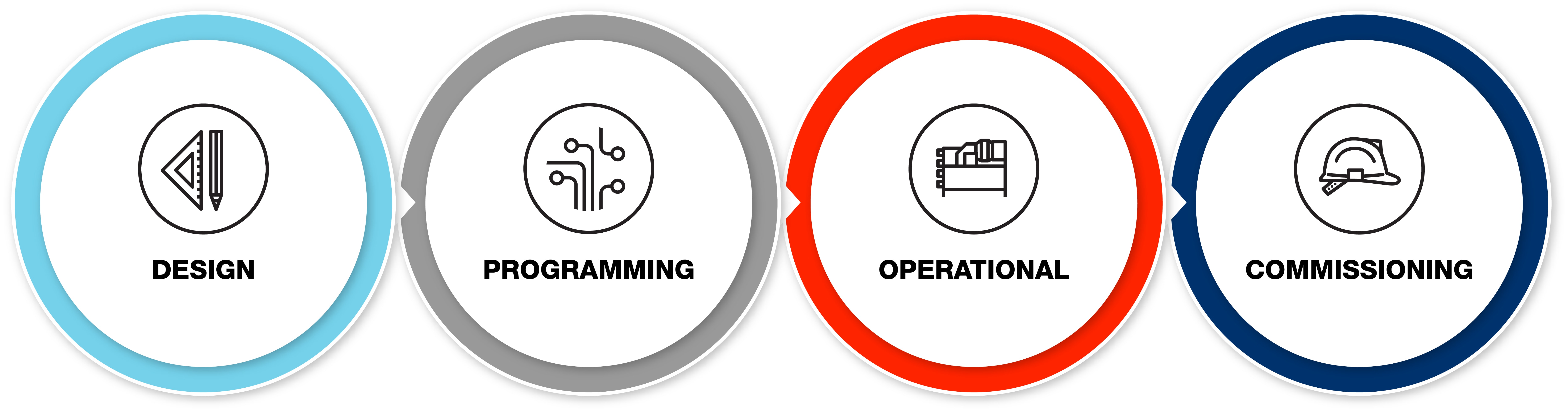

Design Phase

It should be no surprise that when critical systems are being developed, designers and engineers prefer to implement systems and designs that have been proven to be dependable. However, a previous design can rarely be replicated to a new system. Relying on a tool—or set of tools—to assist in designing layouts and sequences that are specific to the project can contribute to the success of the design. Better yet, having a tool that can take pre-engineered, proven, and tested sequences and systems and build them up in a modular fashion to obtain the overall design can be a great way to decrease time and increase reliability in the design phase.

With Trane Design Assist, a free web-based resource, the designer or engineer can select from hundreds of sub-sequences and systems to create thousands of different permutations of a system. Create these designs using industry proven strategies and standards through the tools configurations selections and customize design specifics to meet any project need. From Trane® Design Assist™, several design assets are created including guide specifications, sequences of operation, point lists, and flow diagrams. Knowing that the controls and system design has been carried out with proven elements gives peace of mind that a stable foundation has been set for a reliable plant.

Execution and Programming Phase

With the design documents in hand, it’s now time to transition to the on-site execution of the design. As part of this phase, the implementation of programming and controls sequences starts to take place. Similar to the design phase, having a set of reliable tools that couple the design phase to the execution phase are critical. The sequences and layouts produced from Trane Design Assist not only increase speed and reliability for the designer, but they also increase speed and reliability for the plant programmer since the programs and applications that are to be implemented have been built harmoniously. Having this large library of modular programs that can be built up to fix project and plant complexity creates the desired custom sequence as specified during the design phase.

Operational Phase

In conjunction with a flexible programming library, pre-engineered system control can really be advantageous as it acts as the orchestrator of the entire control system. Having repeatable, pre-engineered components contributes greatly to reliability. Trane Tracer SC+ with its easy-to-use Synchrony Interface has several pre-engineered applications, including Chiller Plant Control, that are the foundation of system control. These applications have been pre-programmed, thoroughly tested, documented, and built into products in order to be scalable, repeatable, and easily applied. It should not be ignored that documentation for these applications, both included in the user interface as well as hard-copy or electronic documentation, are instrumental in the reliability of a system by having owners and operators be able to easily understand the sequence and operation of the applications. This approach of pre-engineered applications, along with robust documentation, now pulls the reliability of the system all the way through the design phase, the execution phase, and now into the operational state of the system.

Commissioning Phase

Not to be overlooked, having a reliable commissioning phase of a project should also be seen as critical. By using design documents, reliable programming libraries, and pre-engineered system applications and application documentation, the commissioning phase can be more easily executed. With sequence documentation that is known from the beginning in the design phase and carried through the project, programmed per the design sequence, commissioning speed and reliability can be increased. Having a commissioning plan aligned with the aforementioned tools and assets can greatly contribute to the success of this phase of the project.

The series of events described above to deliver a reliable chilled water plant relies on a common set of standard tools, standard methods, and standard documentation to minimize risk and help ensure quality and reliability. Trane Design Assist is at the center of this process as it delivers tested proven industry standards, while enabling the uniqueness that comes with each chilled water plant.

About the author

Brian Kirkman, System Application Engineer

Brian Kirkman is a System Applications Engineer for Trane Technologies within the Applied and Sourced Solutions Group based in White Bear Lake, Minnesota. Brian’s primary focus is on system optimization, applied solutions, fulfillment efficiency improvements, and application development.

Brian graduated from Macalester College in St. Paul with a bachelor’s degree in physics and began his career as an electrical designer for an electrical contractor in St. Paul. After several years in the electrical industry, he and his family moved to Columbia, Missouri where Brian worked as a Construction Project Manager at the University of Missouri. In 2012, Brian and his family moved back to Minnesota where he came to Trane as a Project Manager in the Twin Cities sales office. He then transitioned to the Controls Field Group Leader role in the sales office prior to moving into his current role in White Bear Lake in 2018.

Outside of work, Brian enjoys spending time with his wife, middle-school-aged daughter, and elementary-aged boy/girl twins. He enjoys remodeling their outdated house as well as he and his wife coaching and cheering on their kids in many activities – anything from sports to Lego League to orchestra.