Trane® Thermafit™ MWS water-source, multi-pipe (six-pipe) units feature three independent water circuits to satisfy the year-round requirements for heating and cooling in a building. This eliminates the need for duplicate equipment, which significantly reduces floor space requirements, and minimizes the amount of glycol used.

What makes a multi-pipe unit unique?

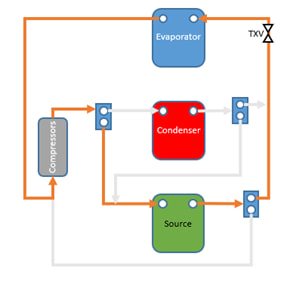

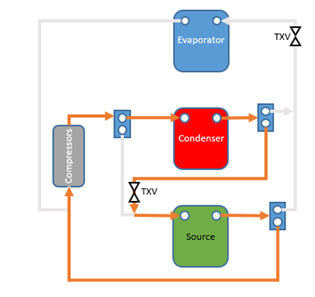

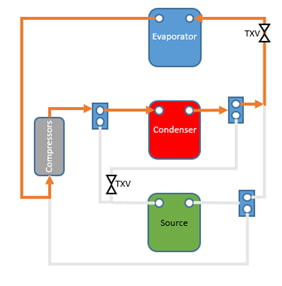

While a typical cooling-only chiller or heat pump includes one heat exchanger (the evaporator) for heat absorption and a second heat exchanger (condenser) for heat rejection, the Thermafit™ MWS unit includes a third heat exchanger, which can be used for either heat absorption or heat rejection. This third “source/sink” heat exchanger is connected to a geothermal loop or other type of heat extraction/absorption loop, and a series of two-way valves direct refrigerant to the three heat exchangers depending on the mode of operation dictated by the unit controller.

- Cooling mode: Similar to a typical cooling-only water chiller, the evaporator absorbs heat from the chilled-water loop, producing cold water for cooling the building; while the source/sink heat exchanger rejects heat, to a geothermal loop for example. The condenser is inactive during this mode.

- Heating mode: Similar to a heat pump, the condenser rejects heat to the hot-water loop, producing hot water for heating the building; while the source/sink heat exchanger absorbs heat, from a geothermal loop for example. The evaporator is inactive during this mode.

- Simultaneous cooling and heating mode (heat recovery): The evaporator absorbs heat from the chilled-water loop, producing cold water, while the condenser rejects heat to the hot-water loop, producing hot water. The source/sink heat exchanger is inactive during this mode.

- 30-, 40-, 50-, or 60-ton modules available, with a minimum of three modules needed for multi-pipe operation. Therefore, system cooling capacity ranges from 90 to 480 tons and system heating capacity ranges from 1350 to 7200 MBh.

- Any module can operate in either cooling mode, heating mode, or simultaneous heating and cooling mode to meet real-time system demands.

- Six-pipe design features three independent loops, eliminating the need for extra heat exchangers and pumps and reducing the overall system volume of glycol and/or chemical treatment.

- Year-round system efficiency enhancement of chilled water and hot water loops by eliminating glycol mixing.

- Compact module size fits through standard doors and elevators for ease of rigging into tight equipment rooms.

- While in simultaneous heating and cooling mode, combined heating and cooling efficiencies up to 28 EER can be achieved.

- Can provide up to 135°F hot water, depending on source water temperatures.

For more information, please visit https://www.trane.com/commercial/north-america/us/en/products-systems/chillers/modular-chillers/thermafit-water-source-modular-multi-pipe-unit-mws.html.

Employing multi-pipe technology in systems

The most recognizable benefit of this multi-pipe technology is its ability to serve both the chilled-water and hot-water needs of a building simultaneously, which can allow for the design of highly-flexible thermal distribution systems. And the third heat exchanger allows for the three water loops to be completely independent, which eliminates the need for intermediate heat exchangers and extra pumps, minimizes the use of glycol and/or chemical treatment agents, and easily allows for the addition of supplemental equipment to one or more of the loops (e.g., a chiller on the chilled-water loop, a boiler or air-source heat pump on the hot-water loop, or a cooling tower or fluid cooler on the geothermal loop).

In addition, several multi-pipe units can be assembled together, forming a multi-pipe bank, to provide even greater flexibility since each circuit can operate in different modes, maximizing overall system efficiency.

For more detail on how to best layout systems using Thermafit™ MWS multi-pipe units, ask your Trane account manager for a copy of the Thermafit™ Multi-Pipe Systems application guide (APP-APG023A-EN), available July 10, 2023.

For more applications updates, subscribe to our Engineers Newsletter.

Engineers Newsletter

About the Author

Dan Gentry, Applications Engineer

Dan Gentry is an applications engineer based in La Crosse, Wisconsin. He joined Trane in 2018 after eight years at another Wisconsin-based chiller manufacturer. Dan first interned at Trane in the Technology Lab while attending school through 2008. His areas of expertise revolve around chiller plants, heat recovery and heat pump systems, and their reliable and efficient design and operation.

Dan graduated from Ferris State University in 2011 with a Bachelor’s Degree in HVAC Engineering Technology and is an active member of ASHRAE. Dan enjoys spending time with his family on the river and relaxing at the family cabin up north.